- Description

- Brand

- Additional information

Description

The Largest Double Chamber Vacuum Sealer

With two chambers of size 730 x 1100 x 280 mm the AVMS 503 is the largest double chamber vacuum sealer of the Audion range. The hygienic construction of the flat working plate ensures an optimsed hygienic operation and low maintenance cost.

This robust double chamber vacuum machine allows you to pack under production conditions and vacuum. To optimise your workforce, safety and ergonomics an (optional) automatic lid is available moving between both chambers.

Made from high grade stainless steel, with a 10 programme control display and configurable with options such heavy duty seal system, sensor control and various seal configurations. User friendly, low maintenance and fully HACCP compatible. All together a robust machine which gives you many benefits.

- Improved ergonomics

- Optimal production output (multiple seal bars)

- Guaranteed operational safety

- Fully customisable for optimised efficiency in every field

- 300 m3/h vacuum pump

Automatic lid option to improve your workflow

The automatic lid brings you competitive advantages:

- Reduces the likelihood of human error

Where work is done, mistakes are made, the saying goes. One of the main advantages of the automatic lid is that it reduces the possibility of human error. This allows you to work more accurately and faster. - Being predictable

Consistency is an important part of any process, and it isn’t possible for humans to perform tasks in exactly the same way every time. The automatic lid removes variation from your packing process, giving you consistent results every time. - It brings safety to a next level. Safety for the operator is key when using an automatic packaging system. Audion supplies the Automatic lid standard with motion sensors. These will guarantee the highest protection level during the entire vacuum packaging process.

- Spend money to save money

Less FTE needed as the Automatic lid reduces the work for the operator. This means that your company does not need to hire extra people to do the work. - Improved ergonomics

Operators experience a huge ergonomic advantage with the automatic lid. Less weight has to be lifted, which improves the working conditions of individual operators and reduces sick leave and stress. - Easier to maintain

The automatic lid doesn’t require much maintenance. It is designed and created with a specific purpose in mind, and they don’t have many moving parts or components that break down easily. - Work faster with less effort

The automatic lid can take care of handlings at a faster pace than the operator, saving packaging time.

Benefits

The Audionvac VMS 503 gives you the following benefits

-

Maximum efficiency Standard 2 seal bars (front – back) for optimised output, different seal bar configurations available. Optimum hygiene Standard double seal (2 wires); convex sealing wires for safer sealing results. Time control To set the time for vacuum, gas and seal cycles for a constant and guaranteed end result. Soft air To pack fragile or sharp products without damaging the products and the bag. Fast cycle Insert plate is standard included, to create a faster cycle and/or to create a better product positioning. 10 program memory Quick selection of the correct program for your products. Ease of use User friendly digital control panel, plug and play. Multicycle Alternate vacuum and gas flush (max 5 cycles) in order to reduce the residual oxygen level. Supplied with gas flush option. Vacuum pump 300 m3/h vacuum pump for a fast packaging cycle. Maintenance friendly Easy pump maintenance and cleaning program; Silicone holders are easily removable for cleaning and maintenance. Flat working plate Stainless steel, for optimised cleaning and hygiene. Construction High quality material, maintenance friendly and easy to clean construction. Warranty 3 years.

Specification

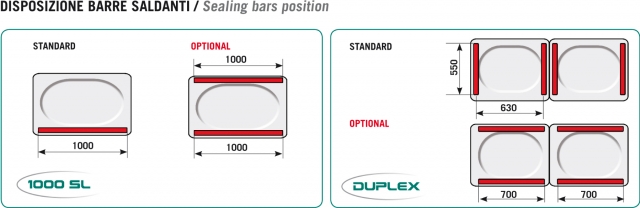

| Seal bar front-back: | 1100 / 1100 mm (standard) |

| Seal bar left-right: | 840 / 840 mm (option) |

| Seal width: | 2 x 3,5 mm double seal (convex sealing wires) |

| Effective chamber size (LxWxH): | (2x) 730 x 1100 x 280 mm (standard) |

| Pump capacity: | 300 m3/h |

| Machine cycle: | 15 – 40 sec |

| Chamber material: | Stainless steel lid and chamber |

| Housing material: | Stainless steel |

| Type of film: | PA/PE, vacuum bags |

| Thickness of film: | 2 x 150 micron |

| Power supply: | 400V-3P-50Hz (standard) |

| Power consumption: | 5,5 – 7,8 kW |

| Weight: | 767 kg |

| Machine dimensions (LxWxH): | 1213 x 2420 x 1160 mm |

Internal or chamber vacuum sealer; with the bag inside the chamber the vacuum pump removes the air. Ideal for smaller, wet, dry or liquid products.

Brand

Audion

Audion Packaging Machines are high quality European made packaging machines with a worldwide service network.

With Audion you have a choice of packaging machines that meet your production requirements. The extensive range of machines covers a large packaging need. Audion Elektro specialise in design and development and manufacture of packaging machinery for the high-end packaging industry. Audion Packaging Machines are sold worldwide and pack everything; from medical, industrial parts to food. Audion Elektro manufacture high quality products for every market, from industrial to retail, standard or custom made, Audion develop a solution for your packaging challenges. Not only for today, but also for the future.Audion Packing Machines:

- Table top heat sealers

- Medical / pharmaceutical / high tech packaging

- Vacuum packing

- Automatic packaging

- Shrink packaging

- Rotary / Band sealers

- Tray sealers

- Packaging material – Consumables

- Packaging machines for E-commerce

Additional information

| Weight | 100 kg |

|---|