- Description

- Brand

- Additional information

Description

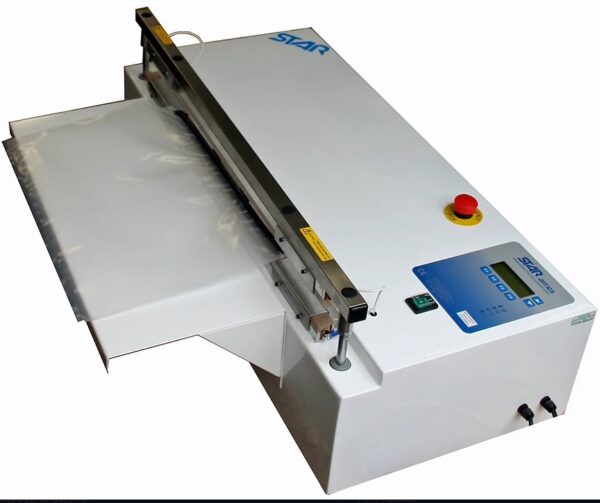

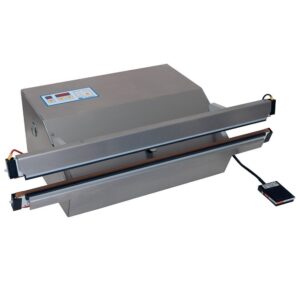

The Star Medical heat sealer has been developed for applications where ease of cleaning is critical, such as in the food, medical and pharmaceutical industries.

The machine body can be built in a number of different designs with the jaws operating vertically (when a product is best sealed laying down) or horizontally (when a product is best sealed standing up). With cylinders moving the top jaw directly, jaw alignment and pressure are much more controllable. With minimal moving parts the Star Medical sealer risks producing no dust particles, unlike continuous rotary style machines, making it ideal for cleanroom operation.

These bag sealing machines are available with all the Star controllers, allowing a wide range of materials to be sealed including polythene bags, laminate ‘stand up’ pouches and PU coated fabrics. With the ARTICS or Medical controller pealable seals can be produced on medical pouch materials such as Tyvek®.

Seal Lengths: 400mm 600mm 800mm 1200mm

Seal Width: 9mm standard 6mm, 12.5mm and 20mm options

Jaw Opening: 50mm standard, 25-200mm options

Max Material Thickness: Over 1000μm (4000g)

Sealing Cycle Time: Typically 4 – 20s Seal Only, 15 – 45s Vacuum Seal

Power Supply: 230V 50/60hZ Single Phase, 115V Optional

Average Power Consumption / Cycle: 0.01 – 0.03kWh

Average Power: Weld 1730W, Cool 125W, Standby 250W

Air Supply: 6 – 8 bar Clean Dry Air

Air Consumption / Cycle: 0.525 – 3.5 NI at 6 bar

Medical Sealer Optional Stainless Steel Stand options

- Horizontal stand

- Vertical stand

- Stainless Steel Support Tray

- Casters

Other options for the Star Medical Vacuum Sealer – Please contact us for pricing:

- Star Medical Seal Cycle Controller

- Electronic Weld Pressure Control

- Twin Panel Push Button Cycle Start with safety relay

- Manual Safety Cutter

- Automatic Cutter

- Parallel Weld for Single Transformer Jaws

- Twin Channel Temperature Control (For parallel weld machines)

- Air or Water Cooled Jaws

- 115V Operation

- Data Upload Program

- Calibration Certification for Temperature and Pressure

- On Site Calibration for Temperature and Pressure

The Star Medical Sealer is available with four different seal cycle controllers:

The MkVI controller offers weld and cool control to the nearest 1/10th of a second and has a built in programme to help counteract the effects of heat build-up during frequent sealing. The MkVI C has weld and cool control to the nearest °C. Adjustment can be made by the keypad with an LCD readout of the settings. The keys can also be locked to prevent unauthorised alteration.

The Star ARTICS controller and Medical controller are suitable where more accurate controls are required, the also allow the element to ramp up to a weld temperature and be held for a time. Cooling time or temperature and element preheat are also included. This allows for a perfect weld to be achieved every cycle. All settings are password protected and the board allows up to 8 different sets of parameters to be programmed. Alarm parameters can be set to give operational tolerances; seal cycle data storage is available with a Medical controller.

Made in the United Kingdom by Star.

This Star Medical Heat Sealer is configured to order so please contact PackSealer for stock lead time and delivery.

Brand

Star Universal

Star Universal British Heat Sealers

Star Universal manufacture heavy duty bag sealers, vacuum sealers and specialised industrial heat sealers in the UK. The range of Star Universal industrial heat sealers, sack sealers and vacuum sealers offers flexibility and reliability whether you are sealing polyethylene bags, medical pouches, laminate vacuum pouches or foil bags. The UK factory ensure the highest of standards and quality assured impulse heat sealers. Many sealers are built to order so it is worth checking first with PackSealer to confirm the availability and delivery lead time. Star Universal have been designing and manufacturing industrial heat sealers for over 40 years. They can produce custom and special purpose heat sealing machinery meeting client requirements across a wide range of industries. If you need a modification to one of the standard heat sealers or something more unusual, PackSealer will work with you and Star to produce a solution based on Star's proven heat sealing equipment. Quality and consistency of seal are the qualities of Star Universal heat sealing machines. Heat compensation technology helps every seal to be the same high standard, even during repeated cycling of the heat sealer. Star’s Mk.VI C, Medical and ARTICS controllers have a heat sensor inserted into the sealing jaws giving unrivalled control of sealing temperature. Star also offer a fully validatable Medical sealer which has been approved by the medical and pharmaceutical sectors. Star Universal industrial bag sealers, sack sealers and vacuum sealers have a well-deserved reputation for durability and reliability. Full spares and service support for the range of bag sealing machines, direct from PackSealer. Please note that Star Universal heat sealers may have to be made to order and are not stocked by PACKSEALER. Please check with PACKSEALER for delivery information prior to ordering.

Additional information

| Weight | 100 kg |

|---|---|

| Jaw Width | |

| Finish | |

| Bag Material | Heavy Duty Thermoplastic, Medium Duty Thermoplastic, Metalised Laminate |

| Capacity | |

| Feature | |

| Seal Length | |

| Seal Width | |

| Sealer Type |