- Description

- Brand

- Additional information

Description

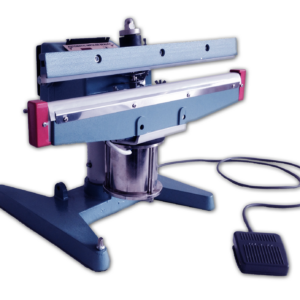

The Senator EVO Vertical Laminate Pouch Continuous Sealer, A vertically arranged rotary heat-sealing machine system dedicated in the

sealing of complex / laminated pouches and films, i.e:

coated foils / papers, poly lined bags and plastic laminates (for other films consult PackSealer).

Designed as a standalone sealing system, ideally suited for use with powders and free flowing products, able to achieve a relatively high production speeds.

This unit is typically suitable for pack weights of up to 5Kg. This sealing system is required to be manually fed and is made up of three main

components, the sealing head, a height adjustable floor stand and a high level belt conveyor.

The SENATOR EVO sealing head is built to an industrial specification, with powerful heaters, coupled with precision made pressure wheels, gives it the ability to seal through heavy

folds and gussets.

The controls feature electronic variable speed drive, a precise digital temperature controller accurately monitors the heaters, ensuring consistent high quality seals.

To provide easy entry into the sealing head, the SENATOR features a belt driven infeed to collect the bag top as it is presented. Once gripped, a firm pressure is maintained as it passes through the

machines sealing processes, ensuring the bag top remains square and the seal line cannot be stressed by either pack weights or operator’s incorrect presentation. At exit, heavy duty pressure wheels producing a distinctive crimp pattern appearance to the seal.

This sealing head is primarily a stainless steel construction with a few internal exceptions of where aluminium and engineering plastics are used.

FEATURES

- Ability to seal through gussets & folds.

- Electronic variable speed.

- Accurate temperature control.

- Proven reliability.

- Simple in operation

OPTIONS:

- Front pack guide

- Non standard seal widths

- Flat Seal Pattern

- Left to right version

- Printing facility

TECHNICAL SPECIFICATION

| Seal Width | 12mm |

| Seal Form | Crimp Pattern |

| Maximum Throat Depth of the Sealer

(to allow the bag tops to pass through) |

70mm |

| Minimum Height Distance Required Inside the Sealer to Produce a Seal | 42mm |

| Infeed Length | 340mm Variable |

| Speed Range | 3 – 12 Metres |

| Pack Weight Able To Be Carried “Unsupported” | 0.25Kg |

| Temperature Range | Maximum 250ºC |

| Power Consumption | 500 Watts |

| Power Supply | 230 Volts |

| Direction Of Feed | Right to Left (Standard) |

| Finish | Stainless Steel Bodywork |

Brand

PackSealer

You PACK it, We SEAL it!

Additional information

| Weight | 100 kg |

|---|---|

| Dimensions | 110 × 90 × 150 cm |

| Installation | No Installation Required, Onsite Installation, Onsite Installation & Training |

| Bag Material | Cellophane, Craft Laminate, Foil Laminate, Heavy Duty Thermoplastic, Light Duty Thermoplastic, Medium Duty Thermoplastic, Metalised Laminate, Side Gusset |

| Capacity | High (up to 2500 seals/day), Low (up to 500 seals/day), Medium (up to 1000 seals/day), Very High (more than 2500 seals/day) |

| Seal Length | 0 to 250mm, 300mm – 450mm, 400mm – 600mm, 550mm – 800mm, 750mm – 1000mm, 1000mm + |

| Seal Width | |

| Sealer Type | |

| Feature | Constant Heat, Vertical Sealer, Continuous Sealer, Stainless Steel |