- Description

- Brand

Description

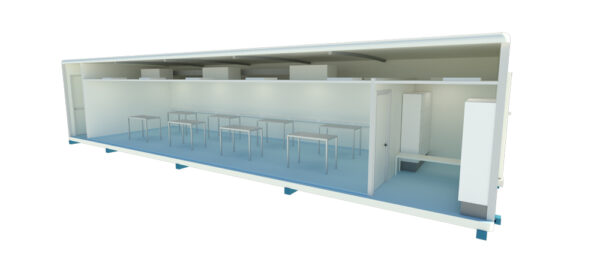

Hygienic Food Safe Room; insulated with lighting & temperature control ideal for food production, preparation and packing.

When internal space is at a premium, an externally located modular foodsafe room can provide the solution; a quick method of increasing production capacity when restrictions on space & timescales are key factors.

A cost effective, flexible solution with little or no disruption to existing processes or production.

Hygienic FoodSafe Room (HFSR’s)

- Internally or externally located

- Fully self-contained

- Internally configured bespoke design

- Temperature control

- Lighting

- Personnel door

Services & products

- Modular / Bespoke construction

- Ideal for product trials, R&D, packaging & production runs

- Working with SiGum offering complementary products & services; high quality, reliable, specialist temperature control solutions.

What are Hygienic Food Safe Rooms?

Hygienic Food Safe Rooms; can also be described as a food processing or food preparation room, designed to prevent contamination of food products & ensure a safe & healthy environment for food processing. Often rooms are temperature controlled environments & can be categorised as AMBIENT, CHILLED & FROZEN.

Delivered finished, sited internally or externally and can be linked to your existing facility.

HFSR’s come with a range of features and capabilities that are most often favoured by manufacturers and businesses conducting food product development, beverage / drinks production, dairy & meat processing.

The features of Hygienic FoodSafe Rooms include:

- Controlled Environments: comfort cooling or temperature specific controlled environment.

- Modular or Bespoke Design: FoodSafe rooms in standard modular sizes of 20m2, 30m2 & 50m2 providing flexibility & can easily be linked to the building externally, meaning you don’t have to compromise any internal space.

- Easy to clean surfaces: walls, floors & ceilings are made of smooth, non-porous materials.

- Sanitary equipment: designed for easy cleaning & sanitizing.

- Temperature Control: to ensure proper storage & processing conditions for food products.

- Pest Control: to prevent pest infestations.

- Cleaning & Sanitizing Protocols: regular cleaning & sanitizing protocols are followed to prevent contamination.

- Personnel Hygiene: personnel follow proper hygiene practices, including handwashing & wearing protective clothing.

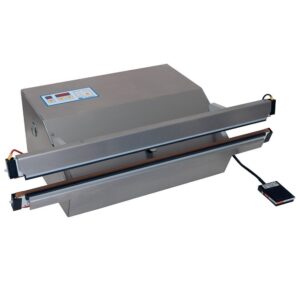

For Hygienic Cleanroom packaging machines see: Medical Sealers | Impulse Heat Sealers | Packsealer

Brand

PackSealer

You PACK it, We SEAL it!

SiGum